Compression and Power

Project Description

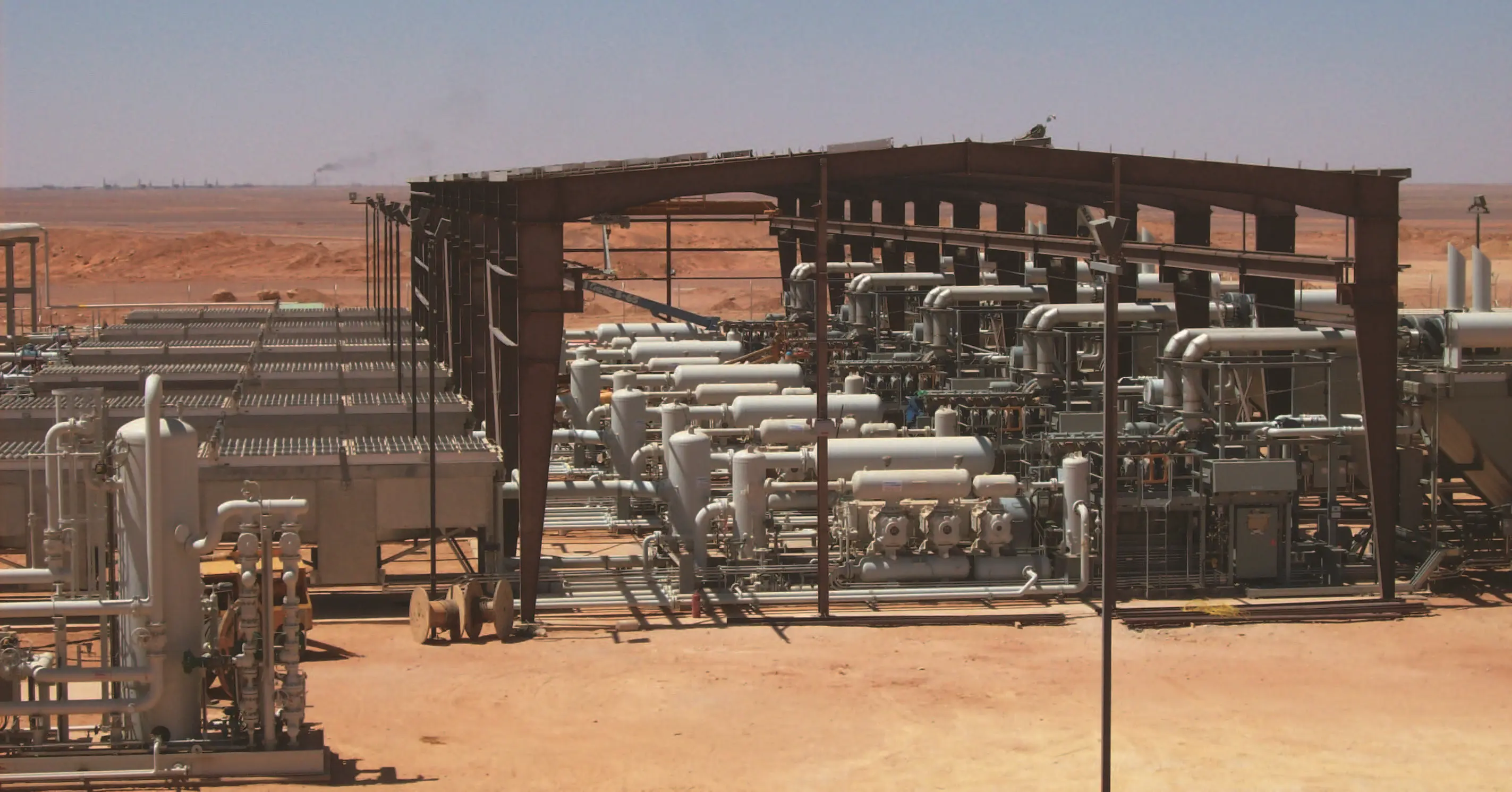

Propak designed and built a compression facility consisting of a combined 35,000 hp of two-stage and three-stage gas compression packages. This plant was designed to re-inject solution gas back into an oilfield formation ending the flaring of associated gas. Solution gas was the only practical fuel source which presented a technical challenge as it is difficult to use untreated as fuel for modern low-emissions engines. This dictated a need to start the engines on this rich fuel and operate under very light load conditions until sufficient fuel gas was produced. Once the facility reached full operation, fuel gas was supplied by a fuel conditioning unit designed and built by Propak. Since this remote field location had no electrical utility source, Propak designed and furnished generators driven by the main engines to provide power for the aerial process gas coolers.

Project Specs

-

Services Provided