Engineering

Engineering Services

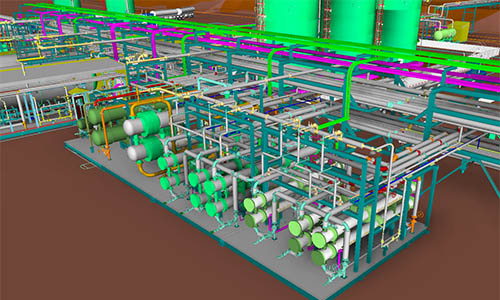

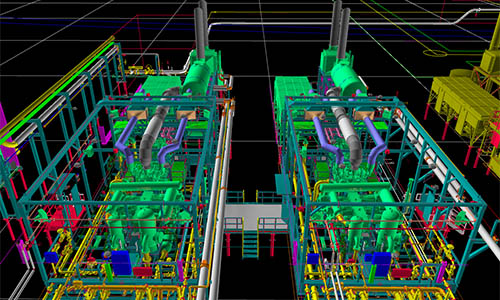

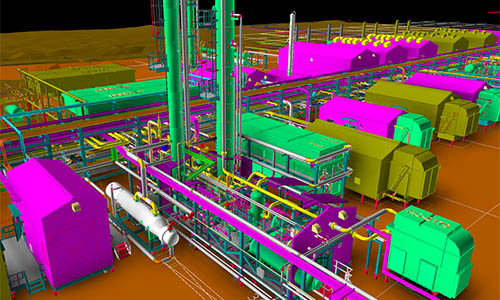

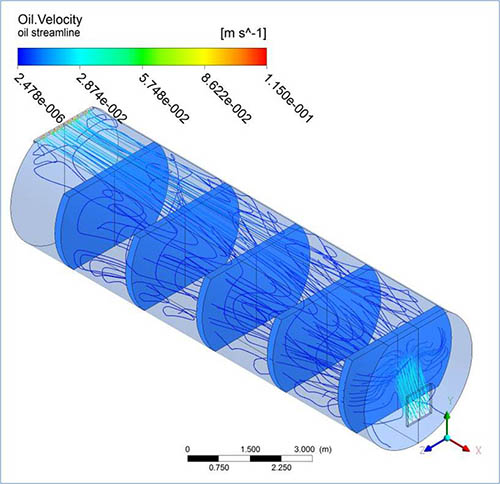

Propak Engineering Services delivers a complete suite of multi-disciplinary engineering services with expertise in a variety of energy processing plants. Our clients benefit from the Propak advantage of a completely in-house project engineering and management team. Engineering services are integrated with shop fabrication and field construction facilitating effective communication, increased efficiency and increased productivity.

Project Cost Estimate Expertise

Complete EPFC Capabilities

Propak Systems is a leader in the design and use of modular design concepts. Our expertise in using this modular approach has proven to be an effective method that minimizes overall project costs, improves project schedules, and allows for a more thorough inspection in a controlled environment. Modularization concepts are preferred based on the following advantages: