Heavy Oil Projects

Project Description

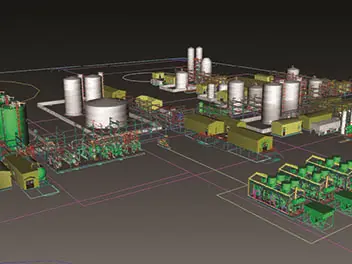

Propak provided a turnkey EPFC solution for this thermal SAGD facility. Based on Propak’s previous small heavy oil facilities and modular facility designs for the natural gas processing industry, a modular thermal SAGD facility as developed. As an entirely modular facility, traditional concrete foundations were eliminated providing significant reductions in the site construction scope of work providing significant cost and schedule reductions. Propak successfully implemented remote I/O technology for this facility. Remote I/O panels were located within each module allowing for instrumentation wire marshalling and pre-commissioning activities to be completed in the shop prior to shipping. The remote I/O reduced field terminations, cable pulls and commissioning activities. This facility was designed, fabricated and constructed with industry leading cost and schedule metrics.

Project Specs

-

Services Provided